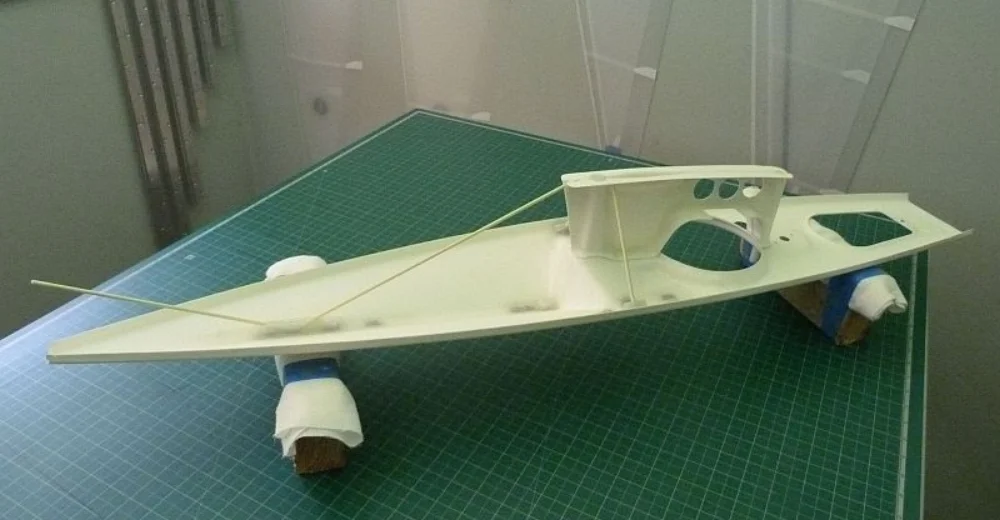

CONSTRUCTION

The following will give some detail of the extraordinary care taken in the build of Plan B. The yacht has been acknowledged as the ‘Best constructed production IOM.’

The one-piece hull and full-deck are moulded separately from layers of high-strength S 'glass fabric reinforced epoxy resin. There are three full layers of fabric in the hull and two in the deck. The superior strength of S ‘glass fabric and post-cured premium epoxy resin makes a durable laminate.

This smooth, uniform, one piece hull moulding, without the interruption and stresses of additional joining and cross-members and with only the longitudinal spine and rudder attachments on the inner surface, will maintain it's flowing low-drag shape without distortion. This has proven so over five years of racing.

Having a separate deck moulding enables the central spine mouldings of integral mast-trunk, keel-case, rudder servo-mount and sheet post-trunk to be bonded and braced with pultruded fibreglass reinforced struts. These struts, together with the deck form, triangulate the jib and shroud mounts, mast trunk and keel case into an integrated structure that encompasses the loadings of the keel, the rig and sails sheeting. With ready access during construction, the stay attachments, deck hardware, winch and switch mountings are reinforced from beneath the deck.

The central spine mouldings, stem and transom mouldings are flanged to give strength and to locate them within the hull and deck. This keel casing spine additionally firmly mounts the rudder servo, incorporates the mast trunk with its secure step, the main-sheet post tubing and too gives strength to the winch mounting. The accuracy of CAD and CAM assures the integrity of the assembly to provide a wide, waterproof bond. The separate stem and transom mouldings give added strength behind the bow bumper and at the back-stay mount.

The one-piece deck moulding is flanged to fasten securely within a moulded channel at the hull sheer line. This forms a strong triple layer at the point of possible side impact. The hull is moulded with an aligned and profiled flange at the keel opening. This flange locates within the keel case of the central spine. Deck openings are rounded and flanged around their perimeters. The rear opening flange and the triple sheer line mouldings give compression strength to resist the winch, rudder, and backstay loads. Yes, this standard is pedantic, but every Plan B yacht built has remained without structural damage.

The bespoke, vacuum moulded winch cover is neatly recessed in the deck.

Final assembly is done within a fixture that gives accurate positioning and alignment of the mast, keel and rudder mountings.

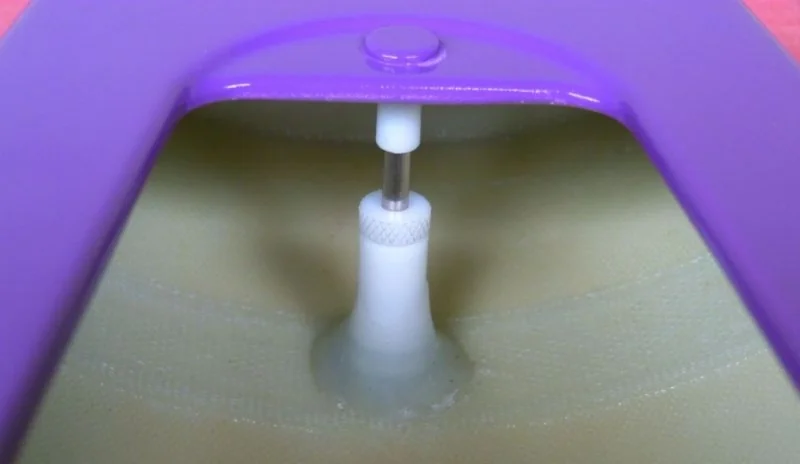

The 316 stainless steel rudder shaft is held in a multi-part acetyl bearing incorporating an adjustable O-ring gland seal and an additional support bearing at deck level.

The hull is finished with two-pack epoxy primer, two-pack automotive acrylic colour coat and two-pack clear top coat. The colour coat can be plain or metallic or can have a pearlescent overcoat. The hard, UV resistant clear top coat is durable and allows minor scratches to be removed by polishing.

A strong, polycarbonate hatch rim is glued in place to accept a substantial, UV resistant polyethylene lid. This is recessed to be flush with the deck.

The bow buffer is a smooth, resilient silicone rubber moulding, either plain or fluted white or black.

The cord jib boom pivot is adjustable, effective and durable in salt water. The coloured cord fades as an indication of age and replacement is quick and easy.

The keel and rudder have pre-moulded, syntactic foam cores. At the core faces is a double bias carbon fabric with the weave at 45 degrees to give torsional stiffness. This low density core is strong in it's own right and is impervious to water ingress.

This moulded core is subsequently compression moulded within a S'glass and unidirectional carbon fibre reinforced epoxy composite shell. Reinforcement is placed and graded to give strength and stiffness. At the leading and trailing edges there is tightly woven S 'glass for impact strength. The construction method assures that the outer shell is one integral moulding of a precise thickness to completely encapsulate the core, without any weakness of joins at the leading and trailing edges. The rounded leading edge minimises stalling at load changes, as in gusts, when quickly sheeting in and accelerating after tacking.

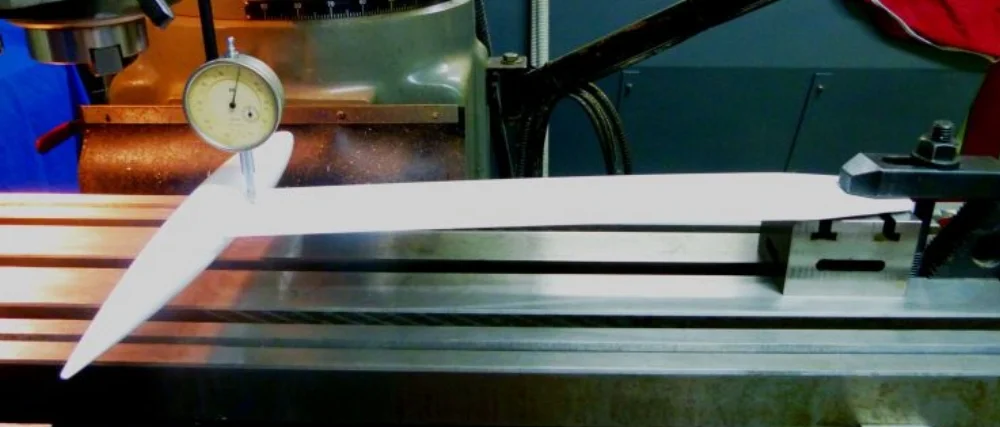

Shown below is the efficient 'Rambler' style rudder which is made in a similar fashion.

The lead ballast is gravity die-cast in a three part steel mould and then, using a CNC machined aluminium mould, is encapsulated within a thin S 'glass and unidirectional carbon fibre reinforced epoxy composite shell. This hard shell gives strength to maintain an accurate, laminar flow, low drag bulb.

The most important, keel, rudder and ballast need six CNC machined metal moulds and various clamps and fixtures for the manufacturing processes. The appendages are critical to the yacht's performance and attention is paid to their mechanical properties and strong mountings within the hull. Of course, all parts are important, only that the appendages are more so than most. The keel is particularly stiff, at only 9 mm. total deflection.

This fixture is used to align the keel, locate the ballast at 2.2 degrees cant and to set the keel length while the two are bonded.

The foils and bulb are finished in white acrylic paint.

The blade rudder with shaft weighs 40 gm. The ‘Rambler’ rudder weighs 35 gm. The keel and bulb are together around 2490 gm, allowing for a later maintenance coat of paint.

All mouldings are oven, post cured to develop their optimum strength.

The yacht build emphasis is on simple, strong and durable using premium materials and fittings.

The weight distribution has been calculated and optimised. With the 1300 mAh battery and high torque rudder servo low in the centre of the boat, the completed yacht needs about 100 gm of corrector weight, attached to the hull, alongside the central spine.